Kala soocida AWS:AWS 5.9

SHARAXA:

Xakamaynta alxanka birta ah waxay leedahay hufnaan sare oo alxanka, waxqabadka farsamada alxanka wanaagsan ee alxanka booska oo dhan.Waxaa si weyn loogu isticmaalaa warshadaha: qaab-dhismeedka dhismaha, gaadiidka, injineernimada buundada, mashiinada macdanta, tareenka, tuubada saliidda, qalabka cadaadiska-gaaska, qalabka korontada, iwm.

MUNAASADDA NO.& QAYBKA:

1. Adeegga OEM sahayda warshadda.

2. Model: ER308 ER308L ER308Lsi ER309 ER309L ER316 ER316L ER316Lsi iwm.

3. Cabbirka siliga MIG: 0.8mm 0.9mm 1.0mm 1.2mm 1.6mm.

4.TIG cabbirka siliga: 1.6mm 2.0mm 2.4mm 3.2mm 4.0mm.

HORDHAC:

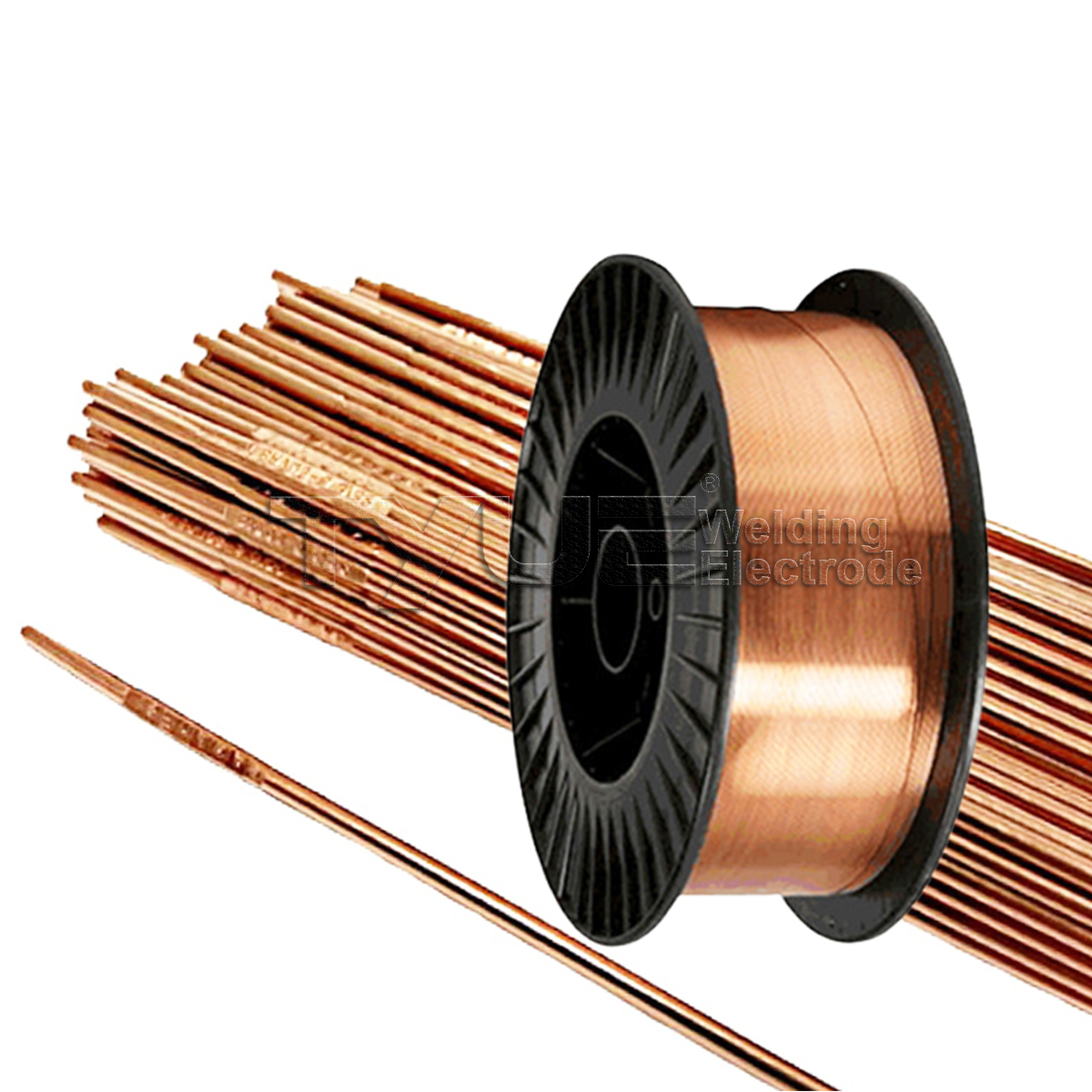

Waxaan bixinaa noocyo kala duwan oo ah silig alxanka birta ah, oo ay ku jiraan Mig adag silig alxanka, Tig rod silig alxanka hoostiisa-arc, oo dhan oo tayo sare leh oo lagu iibiyo adduunka oo dhan.

Marka laga reebo 308 iyo 309, waxaan sidoo kale bixinaa 304, 321, 347, 316L, 310, 2209, iyo 201. Sidoo kale tilmaamo gaar ah sida 318L, 904L, 2594, NiCrMo-3, Ni1.

Baakadaha:

Xirmooyinka siliga alxanka Mig (baakada iyo durbaanka)

Dhexroorka: 0.8 - 2.0mm

Xidhmada: 1 kg/spool, 5kg/spool, 15kg/spool, 20kg/spool, 100 kg/ durbaan, 200kg/ durbaan

Xirmooyinka siliga alxanka tig ul (tuubo caag ah)

Dhexroorka: 1.0 - 5.0mm

Xidhmada: 5 kg / baakidh

Silig alxanka arc quusay

Dhexroorka: 2.5 - 5.0mm

Xidhmada: 20kg / baakidh, 25 kg / baakidh

Baakadaha dhexdhexaadka ah iyo OEM waa la soo dhaweynayaa!

QAABYADA Kiimikada ee Silig-Alxanka Birta Aan-Aan Wanagsanayn:

| Qaabka No. | C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 304 | 0.08 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-11.00 | 0.18 | 0.003 |

| 304L | 0.03 | 0.30-1.00 | 2.00 | 0.045 | 0.030 | 18.00-20.00 | 8.00-12.00 |

|

|

| ER307 | 0.04-0.14 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 8.00-10.70 | 0.5-1.5 | 0.75 |

| ER308 | 0.08 | 0.30-0.65 | 4.30-4.75 | 0.030 | 0.030 | 19.50-22.00 | 9.00-11.00 | 0.75 | 0.75 |

| ER308L | 0.03 | 0.30-0.65 | 1.50-2.30 | 0.03 | 0.02 | 19.5-21.5 | 9.00-11.00 | 0.75 | 0.75 |

| ER308LSi | 0.03 | 0.65-1.00 | 1.60-2.40 | 0.03 | 0.02 | 19.5-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER309 | 0.12 | 0.30-0.65 | 1.00-2.50 | 0.03 | 0.03 | 24.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER309LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 23.0-25.0 | 12.0-14.0 | 0.75 | 0.75 |

| ER316 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 18.00-12.00 | 11.0-14.0 | 2.0-3.0 | 0.75 |

| ER316L | 0.03 | 0.3-0.65 | 1.5-2.3 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER316LSi | 0.03 | 0.65-1.0 | 1.6-2.4 | 0.03 | 0.02 | 18.0-20.0 | 11.0-13.0 | 2.05-2.55 | 0.75 |

| ER310 | 0.08-0.15 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 25.0-28.0 | 20.0-22.5 | 0.75 | 0.75 |

| ER347 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.03 | 19.0-21.5 | 9.0-11.0 | 0.75 | 0.75 |

| ER317 | 0.08 | 0.3-0.65 | 1.0-2.5 | 0.03 | 0.01 | 18.5-20.5 | 13.0-15.0 | 3.0-4.0 | 0.75 |

| ER321 | 0.08 | 0.3-0.65 | 1.5-2.5 | 0.03 | 0.01 | 18.5-20.5 | 9.0-10.5 | 0.75 | 0.75 |

| Qaabka No. | Xoog xamaasada Rm (Mpa) | Awood soo saarid Rel ama Rp0.2(Mpa) | Dheeraynta (%) | Qaabka No. | Xoog xamaasada Rm (Mpa) | Awood soo saarid Rel ama Rp0.2(Mpa) | Dheeraynta (%) |

| 304 | 550 | -- | 25 | ER309LSi | 510 | 320 | 25 |

| 304L | 510 | -- | 25 | ER316 | 510 | 320 | 25 |

| ER307 | 590 | 350 | 25 | ER316L | 510 | 320 | 25 |

| ER308 | 550 | 350 | 25 | ER316LSi | 510 | 320 | 20 |

| ER308L | 510 | 320 | 25 | ER310 | 550 | 350 | 25 |

| ER308LSi | 510 | 320 | 25 | ER347 | 550 | 350 | 25 |

| ER309 | 550 | 350 | 25 | ER317 | 550 | 350 | 25 |

| ER309L | 510 | 320 | 25 | ER321 | 550 | 350 | 25 |

| TIG iyo MIG ka samaysan silig alxanka birta ah | ||||||||||

| YB5092-2005 | AWS | Halabuurka Kiimikada % | ||||||||

| C | Si | Mn | P | S | Cr | Ni | Mo |

| ||

| H08Cr20Ni9Mn7Si | ER307Si | 0.075 | 0.78 | 6.7 | 0.022 | 0.01 | 19.8 | 8.8 |

|

|

| H06Cr21Ni10 | ER308 | 0.045 | 0.45 | 1.9 | 0.02 | 0.009 | 20.8 | 9.8 |

|

|

| H0OCr21Ni10 | ER308L | 0.02 | 0.32 | 1.9 | 0.011 | 0.006 | 20 | 10.2 |

|

|

| H06Cr21Ni10Si | ER308Si | 0.045 | 0.85 | 1.5 | 0.022 | 0.01 | 20.8 | 9.8 |

|

|

| H06Cr24Ni13 | ER309 | 0.06 | 0.45 | 1.9 | 0.019 | 0.009 | 24.3 | 13.2 |

|

|

| H06Cr24Ni13Si | ER309Si | 0.06 | 0.79 | 1.95 | 0.019 | 0.009 | 24.7 | 13.2 |

|

|

| H03Cr24Ni13 | ER309L | 0.02 | 0.42 | 1.8 | 0.02 | 0.01 | 24.8 | 13.2 |

|

|

| H03Cr24Ni13Si | ER309LSi | 0.018 | 0.8 | 1.7 | 0.02 | 0.01 | 23.5 | 13.5 |

|

|

| H21Cr16Ni35 | ER330 | 0.2 | 0.38 | 1.5 | 0.022 | 0.01 | 16.5 | 34.5 |

|

|

| H06Cr19Ni12Mo2 | ER316 | 0.04 | 0.4 | 1.9 | 0.02 | 0.01 | 19.5 | 11.8 | 2.3 |

|

| H06Cr19Ni12Mo2Si | ER316Si | 0.05 | 0.7 | 1.92 | 0.02 | 0.01 | 19.5 | 11.8 | 2.3 |

|

| H03Cr19Ni12Mo2 | ER316L | 0.019 | 0.38 | 1.8 | 0.018 | 0.01 | 19.8 | 12.2 | 2.5 |

|

| H03Cr19Ni12Mo2Si | ER316LSi | 0.06 | 0.85 | 1.7 | 0.022 | 0.01 | 18.8 | 12.6 | 2.4 |

|

| H03Cr17Ni14Mo3 | ER317L | 0.02 | 0.38 | 1.8 | 0.02 | 0.01 | 18.8 | 13.8 | 3.6 |

|

| H08Cr19Ni12Mo2Nb | ER318 | 0.06 | 0.42 | 1.5 | 0.022 | 0.01 | 18.5 | 11.8 | 2.3 |

|

| H07Cr20Ni34Mo2Cu3Nb | ER320 | 0.06 | 0.4 | 1 | 0.022 | 0.01 | 19.8 | 33.3 | 2.8 | Nb0.7 |

| H02Cr20Ni34Mo2Cu3Nb | ER320L | 0.018 | 0.33 | 1.5 | 0.013 | 0.01 | 19.8 | 33.6 | 2.5 | Nb0.35 |

| H08Cr20Ni10Ti | ER321 | 0.06 | 0.45 | 1.5 | 0.022 | 0.01 | 20.8 | 9.8 |

| Ti9xC-1.0 |

| H08Cr21 Ni10Nb | ER347 | 0.055 | 0.48 | 1.8 | 0.021 | 0.008 | 20.8 | 9.8 |

| Nb1xC-1.0 |

| H12Cr26Ni21 | ER310 | 0.09 | 0.5 | 1.66 | 0.02 | 0.01 | 25.5 | 20.5 |

|

|

| H02Cr20Ni25Mo4Cu | ER385 | 0.02 | 0.3 | 1.5 | 0.018 | 0.01 | 20.2 | 24.8 | 4.8 | Cu 1.80 |

| H03Cr22Ni9Mo3N | ER2209 | 0.022 | 0.5 | 0.9 | 0.02 | 0.01 | 22.5 | 8.8 | 3.3 | N0.08-0.20 |

| H04Cr25Ni5Mo3Cu2N | ER2553 | 0.027 | 0.5 | 1 | 0.025 | 0.015 | 24.8 | 5.5 | 3.2 | N0.1-0.25 |

| H1 5Cr29Ni9 | ER312 | 0.09 | 0.38 | 1.5 | 0.022 | 0.01 | 29.5 | 8.5 |

|

|

| H03Cr24Ni13MoL | ER309L Mo | 0.023 | 0.45 | 1.5 | 0.022 | 0.01 | 23.8 | 13.2 | 2.2 |

|

| H05Cr17Ni4Cu4Nb | ER630 | 0.04 | 0.39 | 0.5 | 0.022 | 0.01 | 16.5 | 4.8 |

| Cu;3 Nb;0.28 |

| H08Cr26Ni5Mo2 | ER453s | 0.06 | 0.3 | 0.4 | 0.022 | 0.01 | 25.8 | 4.8 | 2.1 |

|

| H08Cr21Ni10Mn6 |

| 0.06 | 0.35 | 5.5 | 0.022 | 0.01 | 20.8 | 9.8 |

|

|

| H05Cr22Ni11Mn6Mo3VN | ER209 | 0.04 | 0.4 | 4.5 | 0.022 | 0.01 | 21.5 | 10.8 | 2.2 | N;0.20 V;0.18 |